Painting aluminum requires proper surface preparation so that the paint adheres well and forms a durable coating. One of the key steps in this process is degreasing the aluminum before painting. A clean, degreased surface ensures better adhesion of the paint, which translates into durability and aesthetics. In this article, we will discuss in detail how to properly perform this process, using the tools and resources available.

Degreasing aluminum before painting is essential to ensure that the paint adheres evenly to the surface and creates lasting protection. Aluminum, like many other metals, gets covered with a layer of dirt, grease and oil when exposed to the environment, which makes painting difficult. If the surface is not properly prepared, the paint can flake, crack or fall off, leading to corrosion and material deterioration in the long run.

When using aluminum outdoors, atmospheric conditions such as moisture, dirt, grease and even industrial pollutants can deposit on its surface. That's why it's important to degrease aluminum before painting, which helps remove all these unwanted substances and ensure optimal conditions for paint application.

One of the biggest risks associated with improper degreasing of aluminum is the risk of corrosion. Paint that does not adhere properly to the surface will not be able to effectively protect aluminum from weathering and chemical attack. In addition, improper surface preparation can lead to the formation of air bubbles under the paint layer, which weakens its structure and aesthetics.

Degreasing is also important from an aesthetic point of view. Dirt and grease can cause uneven paint application, resulting in stains and streaks. Only a thoroughly cleaned surface allows for a uniform and smooth finish that not only looks aesthetically pleasing, but also has a protective effect.

To degrease aluminum before painting, it is necessary to use the right tools and materials. Here is a list of the most important ones:

The most important part of any degreasing process is the right chemicals. There are various types of degreasers available on the market, both for professional use and for the home workshop. The choice of the right product depends on the scale of the project and the specific requirements of the aluminum surface.

Brushes, sponges, rags or atomizers are often used to apply chemical degreasers. Depending on the product chosen, the method of application may vary. It is important to use accessories that allow the product to be evenly and accurately applied to the aluminum surface.

In some cases, it may be necessary to use mechanical tools such as grinders or wire brushes to remove old layers of paint or stubborn contaminants. Using such tools, however, requires caution so as not to damage the aluminum surface.

The process of degreasing aluminum before painting consists of several steps, the observance of which ensures the best final results. Below is a detailed step-by-step guide on how to degrease aluminum:

Before you start degreasing, make sure the work area is properly prepared. It should be well ventilated to avoid inhaling harmful chemical fumes. Also protect adjacent surfaces and objects so that they are not accidentally damaged.

Your search for the right degreaser should begin with an analysis of the formulations available on the market. Choose the one that is suitable for your needs and the type of surface. You can consult a professional or a salesperson at a chemical supply store to get detailed information on available products.

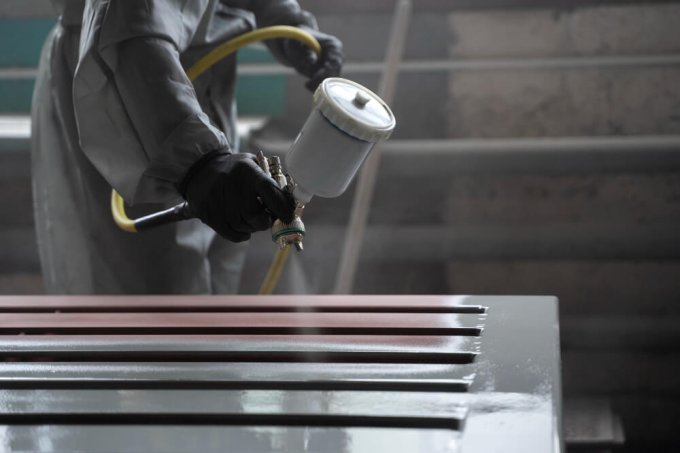

Apply the degreaser to the aluminum surface according to the manufacturer's instructions. Use a brush, sponge or atomizer to spread the product evenly. Remember to work in a ventilated area and use protective gloves. After applying the product, let it work for a specified period of time, usually a few to several minutes.

After the time indicated by the manufacturer, rinse the aluminum surface with water to remove any residual degreaser along with dissolved contaminants. Make sure the surface is thoroughly cleaned and no chemical residues remain on it. Then dry it, preferably using compressed air or lint-free cloths.

After degreasing the surface, check that it is properly prepared for painting. You can perform a simple water droplet test - if the water spreads evenly over the surface, it means it is well degreased. However, if the water droplets cluster in one place, the degreasing process may need to be repeated.

In the process of degreasing aluminum before painting, it is crucial to follow the manufacturer's instructions for the chemicals used and to ensure proper working conditions. Also, remember to use appropriate personal protective equipment, such as gloves, protective masks and goggles.

To achieve the best results when degreasing aluminum before painting, it is worth noting a few key practices that will make the entire process easier and more effective.

Before you start degreasing, ensure that the aluminum surface is free of large mechanical contaminants, such as rust, old layers of paint or other deposits. The main use of a wire brush or grinder allows you to remove the most stubborn contaminants, making the subsequent degreasing process easier.

There are different types of degreasers on the market, which vary in chemical composition and effectiveness. Before performing a full degreasing of the surface, it is a good idea to test several preparations on a small, less visible piece of aluminum. This will enable you to choose the most effective agent and avoid unexpected chemical reactions or damage to the surface.

During the degreasing process, it is necessary to ensure proper working conditions. Work in a well-ventilated room to avoid negative health effects from chemical fumes. It is also important to use personal protective equipment such as gloves, protective masks and goggles.

If you work with aluminum on a regular basis, it's worth considering regular maintenance. Periodic degreasing and cleaning of aluminum will prevent the buildup of contaminants, making future painting easier and extending the life of the material.

To hone your skills, it's a good idea to keep records of the degreasing agents and techniques you use. Make a note of which preparations proved most effective, what working conditions were most optimal, and what results were achieved. Such analysis will allow you to better prepare for future projects and can become a valuable resource.

The process of degreasing aluminum before painting can be complicated, especially for those who do not have much experience working with metals. There are several common mistakes that can affect the quality of the final result.

Not all degreasers are suitable for use on aluminum. Choosing the wrong chemical can lead to surface damage or insufficient degreasing. To avoid this mistake, always read manufacturers' labels and look for agents dedicated to working with aluminum.

One of the most common mistakes is inaccurately removing contaminants before degreasing. Even the best chemicals will not be effective if the aluminum surface is covered with a thick layer of dirt, grease or old paint. Carefully clean the surface mechanically before degreasing.

Another mistake is applying too little degreaser or spreading it unevenly. For larger areas of aluminum, this can lead to leaving greasy spots or improperly cleaning the material. To prevent this, make sure you use the right amount of product and apply it evenly.

Each degreaser has a specific duration of action that is necessary to remove contaminants from the surface. Shortening this time can lead to insufficient degreasing. To avoid this mistake, always follow the manufacturer's recommendations for the product's operating time.

After applying a degreaser, always rinse the aluminum surface thoroughly with water and dry it before painting. Skipping this step can lead to residual chemicals on the surface, which can react with the paint and weaken its adhesion.

We asked several experts in the painting industry about their experiences and recommendations for degreasing aluminum before painting. Here's what they had to say:

"Thorough degreasing of aluminum is a key step in preparing the surface for painting. In my practice, I often encounter cases where ignoring this step leads to later problems with the paint. I always recommend using degreasers dedicated to metals and carefully rinsing and drying the surface after use."

"The role of proper degreasing of aluminum before painting cannot be overemphasized. Choosing the right chemical preparation and using the right technique are steps that determine the quality and durability of the painted coating. When working with different metals, I always pay attention to thoroughly remove all dirt and grease before applying paint."

"In my educational work, I often emphasize the practical aspects of preparing metal surfaces for painting. Ensuring that students are properly involved in the aluminum degreasing process is key. Using the right degreasers and techniques, we teach future professionals how to effectively prepare surfaces for further processing and painting. It is extremely important that young people understand the importance of this step."

Degreasing aluminum before painting is a key step that ensures the durability and aesthetics of the painted surface. Following proper procedures and using the right chemicals are steps that determine the success of the entire process. Remember to test the available formulations, maintain work safety and carefully remove all contaminants. With these tips, your projects will not only be aesthetically pleasing, but most importantly long-lasting and resistant to the elements.