Welding aluminum is a process that requires a precise approach and thorough preparation. Cleaning aluminum before welding plays a key role in ensuring the durability and aesthetics of the weld. Aluminum is highly reactive when in contact with air, resulting in the formation of oxides on its surface. Without proper cleaning, these oxides can lead to poor welds, inclusions and impurities that reduce the quality of the work performed. In this article, we will discuss in detail the methods and accessories needed to effectively clean aluminum before welding, provide best practices and tips, and share the opinions of experts in the field.

Aluminum, due to its unique physical and chemical properties, is a material that requires special procedures when preparing for welding. Aluminum oxide, which naturally forms on the surface of this metal, is one of the most difficult metal oxides to remove. This oxide is very stable and its presence can lead to serious problems in the welding process.

First, aluminum oxide has a higher melting point than aluminum itself and does not melt during the welding process. This can lead to a situation where the oxide remains on the surface during welding, causing discontinuities and weakening the weld. In addition, the presence of grease, lubricants and other impurities can lead to porosity in the weld and the introduction of contaminants. Oxides and impurities can also affect the inhomogeneity of the mechanical properties of the weld, resulting in instability.

Understanding the importance of cleaning aluminum prior to welding is crucial for any welder who strives for the highest quality and durability of the weld. In this section, we will outline the main risks of not cleaning properly, as well as the benefits of proper aluminum preparation.

Check also the offer of the manufacturer of aluminum profiles

Mechanical methods are one of the most common ways to clean aluminum before welding. The most popular techniques include brushing, grinding and scraping. Each of these methods has its own specific applications and advantages.

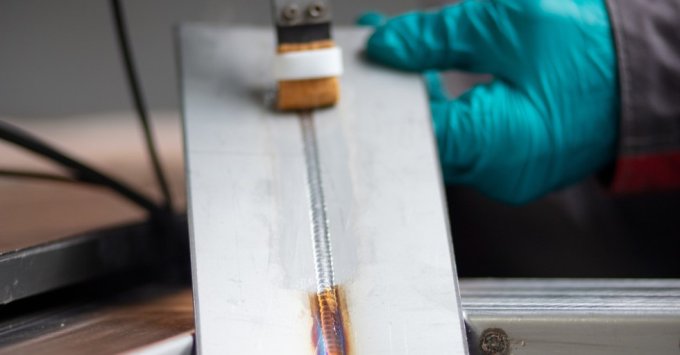

Brushing is one of the primary methods of removing oxides from aluminum surfaces. Using brushes made of stainless steel wire is one of the most effective methods for effectively cleaning aluminum before welding. The key is to use brushes that have not been previously used on other materials to avoid cross-contamination. When working with aluminum, it is recommended to use soft wire brushes that will not damage the surface of the material.

Grinding is another effective method, especially when working with larger surfaces or more stubborn oxides. Using the right tools, such as angle or orbital sanders with the right abrasive discs, can quickly and efficiently remove the top layer of oxide. It is worth remembering to always use new discs when machining aluminum to avoid introducing contaminants from other materials.

Scraping, although it may seem like an outdated method, is still used in many workshops. This procedure is performed with sharp tools such as knives or chisels, allowing precise control over the removal of oxides from hard-to-reach areas. Scraping is particularly useful for cleaning edges or details where other methods may not be thorough enough.

Each of the above mechanical methods has its place in cleaning aluminum before welding. The choice of the appropriate technique depends on the specifics of the particular task, the type and degree of contamination, and the tools available. A combination of different methods often yields the best results, providing a precisely cleaned surface ready for welding.

Chemical methods of cleaning aluminum before welding are very effective, especially when dealing with harder-to-remove contaminants or oxides. Chemicals can penetrate and dissolve oxides and contaminants, which mechanical methods are not always able to achieve. It is worth noting, however, that the use of chemicals requires adherence to strict safety procedures.

One of the most popular chemicals used to clean aluminum before welding is alkaline solutions. The use of a mixture of sodium hydroxide (NaOH) is common because it effectively dissolves aluminum oxides. The process begins by applying the solution to the aluminum surface, followed by a short dwell period, followed by a thorough rinsing with clean water. Once the reaction is complete, the surface should be protected from reoxidation.

Nitric acid (HNO3) is another effective chemical for cleaning aluminum. This chemical is mainly used for passivation, that is, to remove a thin layer of oxides and protect the surface from corrosion at the same time. As with any acid, exercise caution, use appropriate personal protective equipment and work in a well-ventilated area.

Organic solvents such as acetone, isopropyl alcohol and methylene chloride are used to remove fats, oils and other organic contaminants from aluminum surfaces. The use of these agents is particularly useful before using other cleaning methods, as the removal of grease contaminants allows other chemical or mechanical techniques to work more effectively.

When using chemical aluminum cleaners, it is extremely important to follow safety rules. The use of gloves, safety goggles and appropriate clothing is essential to protect against the effects of aggressive chemicals. These processes should be performed in well-ventilated areas to avoid inhaling harmful fumes.

Chemical methods of cleaning aluminum before welding are very effective, but require a precise approach and caution. The use of appropriate chemicals allows to obtain a clean surface ready for welding, which positively affects the quality and strength of the weld.

Preparing aluminum for welding requires using the right tools and following best practices to ensure the highest quality weld. In this section of the article, we will discuss in detail the procedures and tools that are necessary to properly prepare aluminum. We will also highlight what steps are worth taking to get the best results.

Choosing the right tools is key to successfully cleaning aluminum before welding. As mentioned earlier, stainless steel wire brushes, appropriate grinding discs and scraping tools are essential tools in the preparation process. It's also a good idea to stock up on clean cloths and solvents such as acetone to clean fats and oils from surfaces.

Cleaning technique is as important as the choice of tools. When brushing, always proceed in one direction to avoid leaving dirt on the surface. Sanding should be done evenly, using tools of the right granularity to ensure a uniform surface. Scraping should be precise to remove contaminants without damaging the aluminum surface.

Once the aluminum has been thoroughly cleaned, it is extremely important to begin welding immediately. Aluminum quickly forms oxides on its surface, so a delay in starting welding may require re-cleaning. To minimize the risk of reoxidation, suitable protective measures such as protective fabrics or films can be used to protect the surface until welding.

Choosing the right shielding gas also affects the quality of the weld. Argon is often used as a shielding gas for welding aluminum, as it provides sufficient protection against oxygen from the atmosphere. It is also important to ensure adequate gas flow during welding to protect the surface from oxidation.

Preparing aluminum for welding requires not only the right tools and technique, but also discipline and accuracy in following the recommended procedures. By following best practices, the highest quality weld can be achieved, which is critical in many industrial and craft applications.

In this section, we will present the opinions and advice of experts associated with the welding industry on cleaning aluminum before welding. This knowledge, based on both practical and theoretical experience, will help you better understand key aspects of aluminum preparation.

We spoke with Zbigniew Kowalski, an experienced welder working for more than two decades in the metallurgical industry. Mr. Zbigniew stresses that the most important element in the aluminum preparation process is consistency and patience. "You can't afford to take any shortcuts during cleaning. Any inaccurate removal of contaminants translates into weld quality. I especially recommend brushes that are not stepped on and not previously used for other materials. It is such details that affect the final result."

Industrial chemistry experts suggest that choosing the right chemicals can significantly improve the process of cleaning aluminum before welding. Dr. Anna Nowak, a chemist specializing in metal materials, points out: "The use of nitric acid or sodium hydroxide must be strictly controlled, but when used correctly these chemicals give excellent results. It is important to rinse the surface thoroughly after chemical cleaning to avoid residual chemicals that can affect the welding process."

For many years, many practical tips have been circulating in the industry that can greatly simplify the process of preparing aluminum for welding. One such idea is to use simple tests to check the effectiveness of cleaning. Marek Sparrow, a welder with many years of experience, says: "One of the tricks I use is to use a simple water drop test. If the water droplet spreads evenly over the surface, it means that the surface is properly cleaned and free of oily contaminants. If, on the other hand, the water condenses into beads, the surface needs further cleaning."

Avoiding common mistakes can also significantly affect the quality of the weld. One common problem is using tools that were previously used for other metals, leading to cross-contamination. Another mistake is leaving chemicals on the surface too long, which can lead to weakening of the metal's structure. Experts stress that the key to success is strict adherence to procedures and constant monitoring of the process.

Industry experts stress that cleaning aluminum before welding is a process that requires precision, proper knowledge and discipline. Their opinions and tips can provide valuable support to both experienced and novice welders in their quest for perfect results.

Cleaning aluminum before welding is a key step in preparing the material for the process. Mechanical methods, such as brushing, grinding or scraping, and chemical methods using alkaline solutions, nitric acid and organic solvents are the primary techniques for removing oxides and contaminants from aluminum surfaces. Choosing the right tools, techniques, and carefully following safety and personal protection rules when using chemicals are integral to successful aluminum preparation.

Expert opinions and advice on aluminum cleaning can prove extremely valuable to welders, both experienced and novice. Awareness of mistakes to avoid, such as cross-contamination of tools, and the use of practical tips, such as cleaning effectiveness tests, allow for superior weld quality and durability.

Cleaning aluminum before welding is a process that requires precision, discipline and continuous improvement of one's skills. Adhering to best practices and learning from experienced professionals allows you to achieve optimal results when working with this demanding material.